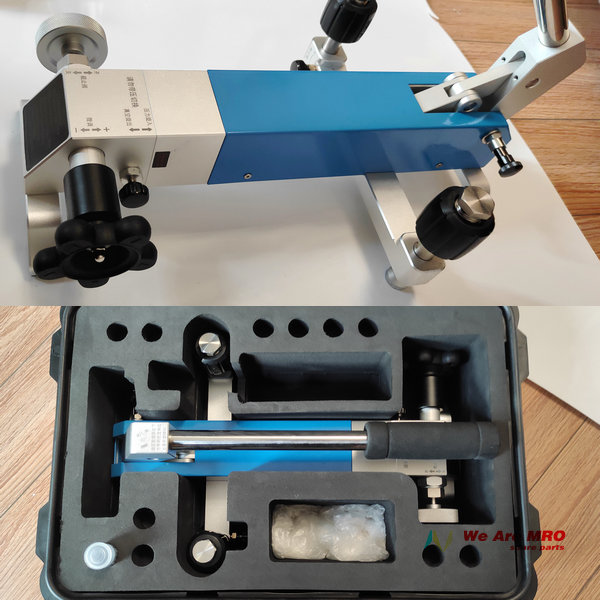

Pneumatic High Pressure Test Pump

Pressure range:95% vacuum to 16Mpa ( 160 bar ); -0 .095 to 16Mpa

Temperature:0 to 50℃

Humidity:< 85%RH

Adjustment resolution:0.1mbar

Overpressure Safety Limit: 180 bar

Pressure media:Air

Net Weight: 5.76 k g

Dimensions: 3 8 7 × 250 × 160mm (long × Wide × High)

Standard Table Interface:M20×1.5 (customized:1/4NPT,1/2NPT,G1/4,G1/2)

Characteristics of portable high-pressure pressure pump

1. Open structure, high-quality aluminum alloy, stainless steel components.

2. The pressure pump adopts a lever pressure structure, which is labor-saving and fast.

3. Micro adjustment and pressurization adopt a spiral pressurization method, which is fast and labor-saving.

4. High reliability, non leakage, and high engineering quality.

5. Suitable for calibration of pressure instruments such as pressure gauges, pressure transmitters, pressure switches, and pressure sensors.

6. The fine-tuning valve adopts a spiral method, with small friction, stable pressure rise and fall, and high accuracy.

7. It has two quick connectors for more convenient testing.

8. Equipped with a built-in filter and drain outlet, there is a filter screen below the output outlet, and there is a drain outlet above the product. If impurities are detected in the product, they can be automatically discharged to the drain outlet.

The portable high-pressure pressure pump mainly consists of a pump body assembly, a pressure rod assembly, a shut-off valve, a fine adjustment valve, a vent valve, a directional valve, and two M20 × 1.5 quick pressure output connector composition.

1. Pump body assembly: composed of output bracket, pre pressure pump body, reversing valve body, piston component, etc., used for pressure generation, retention, control, and output.

2. Pressure rod component: composed of handle rod, connecting rod, connecting block, bearing, etc., used for pressure making operations.

3. Stop valve: used to stop the pressure between the pre pressure pump body and the pre pressure pipeline.

4. Fine adjustment valve: used for fine adjustment of pressure.

5. Air release valve: used to remove pipeline pressure after calibration work is completed.

6. Reversing valve: used for switching between vacuum and positive pressure working modes.

7. Output connector: used to quickly connect standard meters and checked meters.

Note: Install a standard gauge on the left end and a check gauge on the right end, which is conducive to the discharge of dirt from the check gauge.

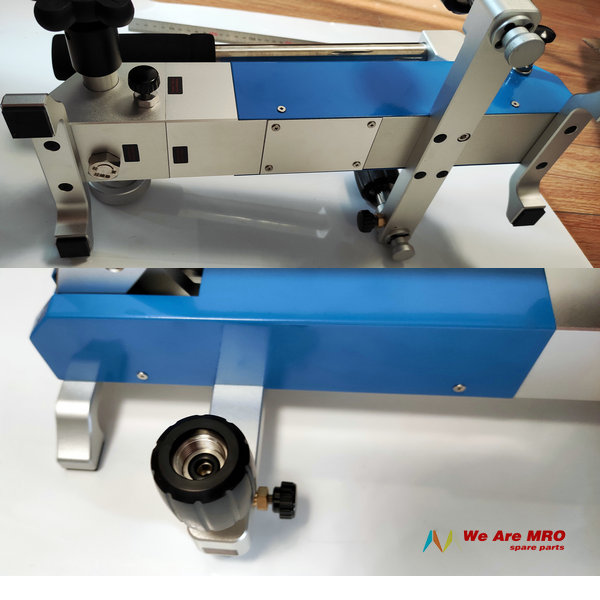

1

Pressure/vacuum selector

(Positive pressure: pull it out; Vacuum: push it in)

Do not switch while unit is under any pressure

2

Isolation valve/ shut-off valve

isolates the calibration volume from the hand pump and

check valve, ensure measurement stability

3

Standard Table Interface

Used to connect standard pressure gauges( M 20× 1.5)

4

Pressure handle

Upward lifting and downward pressing

5

Maintenance cleaning port

Filter oil and impurities into the pressure system

6

Fine adjust handle

Accurately adjust the applied pressure. Turn Clockwise to increase pressure

7

Vent valve/relief valve

Loosen and release the pressure inside the pump, tighten the valve to pressurize

8

Test interface/Quick connector

Connect the calibrated pressure instrument interface(M20 ×1. 5)

9

Pressurized handle locking pin

Locking the pressure handle (easy to carry)