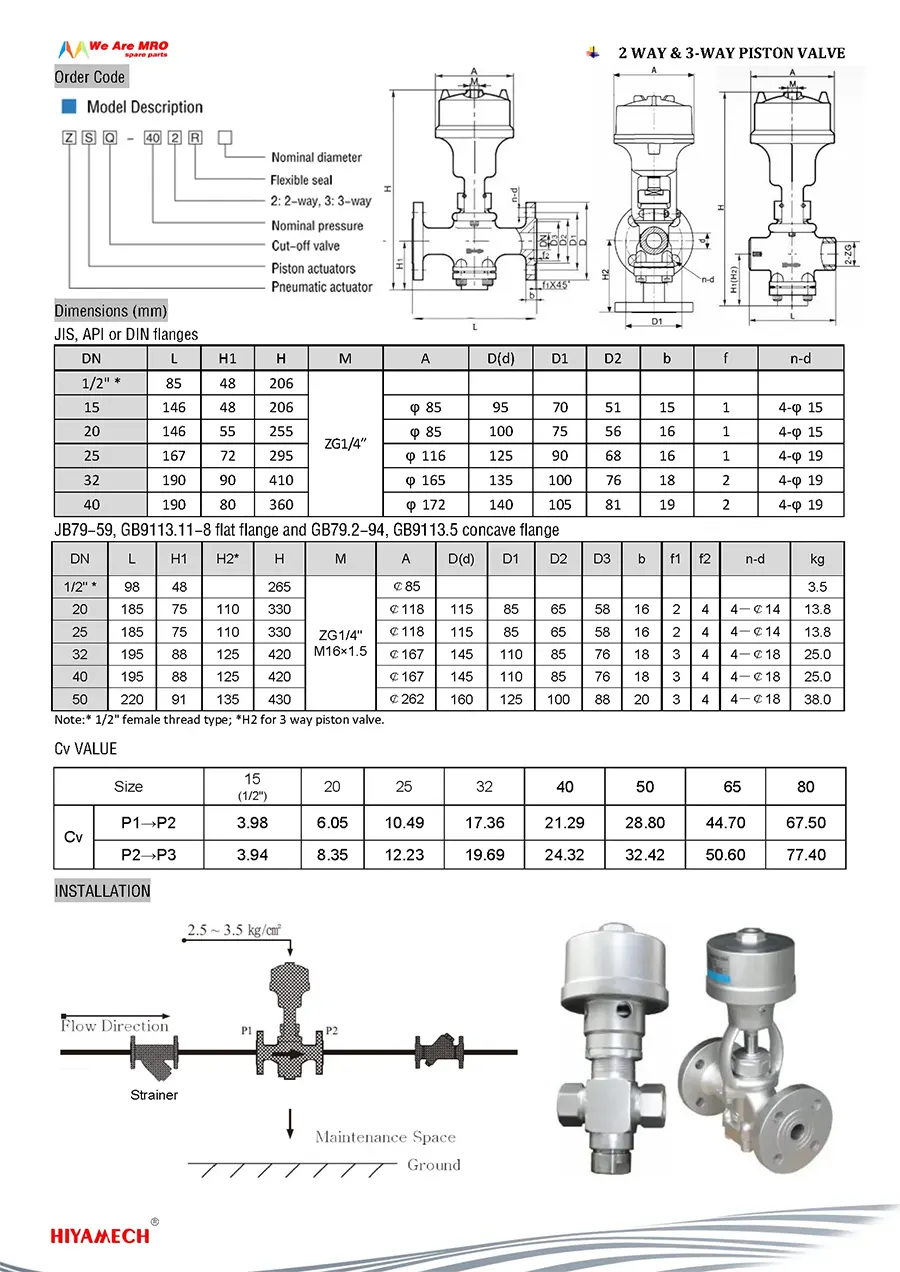

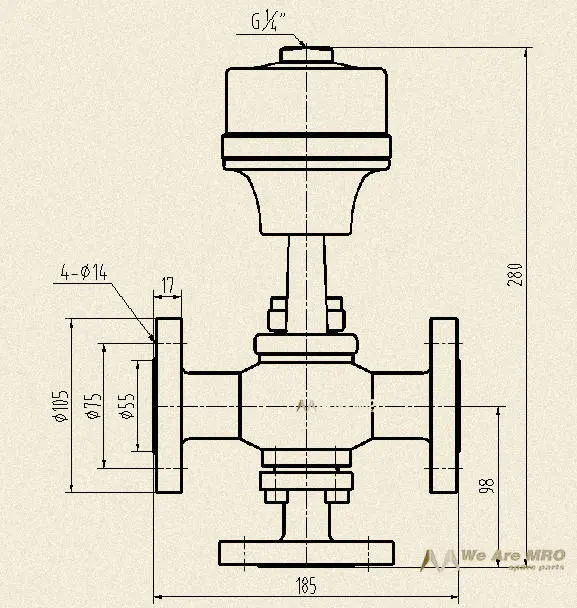

ZSQ-403R DN25 Pneumatic 2-position shut-off valve

The pneumatic two-position shut-off valve is one of the automation elements in the industrial production process and the actuator in the pneumatic unit combination instrument. It opens or cuts off the flowing medium (water, steam, etc.) in the pipeline according to the signal supplied by the control instrument, so as to meet the requirements of the system on pressure, temperature, flow and other industrial parameters.

This model is a new generation of precision cast stainless steel shut-off valve designed by the Company by absorbing advanced foreign technologies. It combines the advantages of excellent material, beautiful appearance, light weight, small volume, long service life and convenient installation and maintenance. Suitable for use on nitrogen sulfiding. Its main performance indicators reach the level of similar imported valves.

Executive standard of this product: HG/T3- 1989 Pneumatic Two-position Shutoff Valve for Rubber Machinery

Applicable to flange connection system adopting JIS (Japanese Industrial Standard), API (American Petroleum Institute Standard) or DIN (Federal German Industrial Standard).

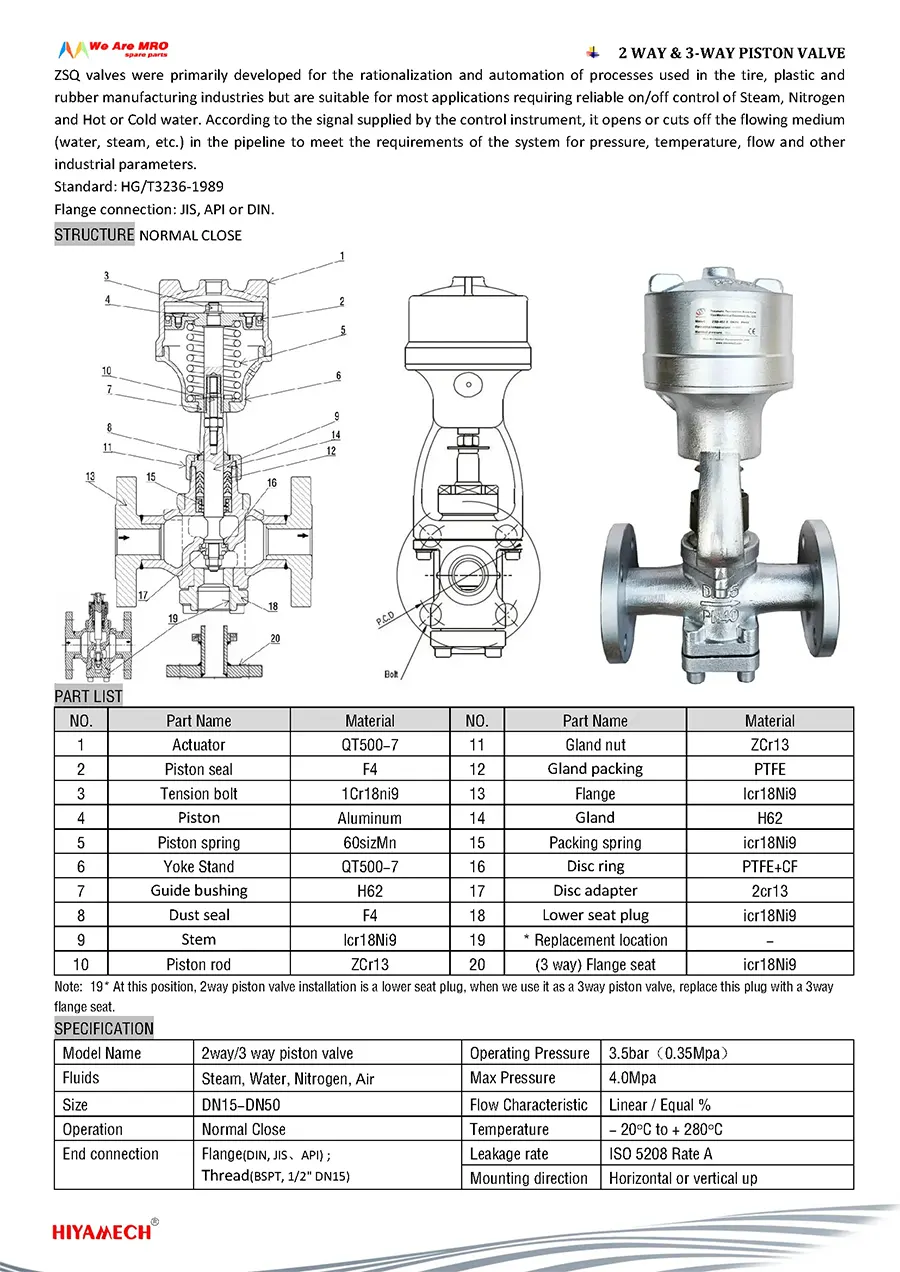

Structure and operating principle:

The pneumatic two-position shut-off valve is composed of the piston actuator and the shut-off valve. When there is no signal, the valve core is closed on the upper valve seat by the preload of the spring; When there is signal input, the piston pushes the valve rod to move downward to close the valve core on the lower valve seat. The three-way shut-off valve and the two-way shut-off valve are different from the lower end. The former is equipped with a nozzle and can be connected to another loop pipe; The latter is a closed bonnet.